Description

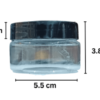

Pet Jar 50 g

Polyethylene Terephthalate (PET) jars have gained immense popularity in various industries, including food, cosmetics, pharmaceuticals, and personal care. PET is a type of plastic known for its durability, clarity, and recyclability, making it an ideal packaging solution for a wide range of products. PET jars are lightweight, shatter-resistant, and cost-effective compared to glass and other packaging materials.

This comprehensive guide will explore the benefits, uses, properties, sustainability aspects, and customization options of PET jars, helping businesses and consumers understand why they are a preferred choice in modern packaging solutions.

1. What is PET?

Polyethylene Terephthalate (PET) is a type of thermoplastic polymer resin from the polyester family. It is widely used in the packaging industry due to its strength, clarity, and resistance to moisture and chemicals. PET is formed by polymerizing ethylene glycol and terephthalic acid, creating a durable and flexible material that can be molded into various shapes and sizes.

2. Properties of PET Jars

PET jars offer several beneficial properties that make them a top choice for packaging:

- Lightweight: PET jars are significantly lighter than glass, reducing transportation costs and making them easier to handle.

- Durability: PET is strong and impact-resistant, preventing breakage and ensuring product safety.

- Clarity: PET provides excellent transparency, allowing consumers to view the product inside.

- Chemical Resistance: PET jars do not react with most substances, making them suitable for cosmetics, food, and pharmaceuticals.

- Moisture Barrier: PET protects against moisture and humidity, keeping products fresh and extending shelf life.

- Recyclability: PET is 100% recyclable, contributing to sustainability efforts and reducing environmental impact.

3. Advantages of Using PET Jars

PET jars are widely chosen across industries due to their numerous benefits, including:

A. Cost-Effectiveness:

- PET is cheaper to manufacture compared to glass and metal packaging.

- The lightweight nature reduces shipping and handling costs.

B. Safety and Durability:

- Unlike glass, PET does not shatter, making it safer for handling and transportation.

- Strong impact resistance ensures that the packaging remains intact even when dropped.

C. Versatility:

- PET jars can be used for a variety of products such as food, cosmetics, pharmaceuticals, and household items.

- Available in different shapes, sizes, and designs to meet specific product needs.

D. Sustainability:

- PET is recyclable and can be repurposed into new bottles, containers, and textiles.

- Reduced carbon footprint compared to glass manufacturing and transportation.

4. Uses of PET Jars in Different Industries

PET jars are widely used across multiple industries due to their adaptability and reliability. Some of the major industries utilizing PET jars include:

A. Food & Beverage Industry:

- Used for packaging honey, jam, peanut butter, sauces, and pickles.

- Ideal for dry food products like nuts, candies, and snacks.

- Airtight seals prevent contamination and extend shelf life.

B. Cosmetics & Personal Care:

- Commonly used for creams, lotions, scrubs, and hair care products.

- Lightweight and easy to handle for daily use.

- Customizable designs to enhance brand visibility.

C. Pharmaceutical Industry:

- PET jars are widely used for storing tablets, capsules, powders, and ointments.

- Provide airtight protection against moisture and external contaminants.

D. Household Products:

- Used for detergents, liquid soaps, and cleaning agents.

- Durable and resistant to chemical reactions.

5. Manufacturing Process of PET Jars

The production of PET jars involves several steps:

A. Polymerization:

- PET is synthesized from ethylene glycol and terephthalic acid.

- The polymer is then processed into small pellets.

B. Preform Manufacturing:

- PET pellets are melted and molded into preforms (small test-tube-shaped plastics).

- Preforms are then stored and transported to manufacturers for further processing.

C. Blow Molding:

- Preforms are heated and blown into the desired jar shape using a mold.

- The blow-molding process ensures uniform thickness and structural integrity.

D. Quality Control & Finishing:

- Each PET jar undergoes rigorous quality checks for clarity, strength, and sealability.

- The jars are then labeled, capped, and prepared for distribution.

6. Sustainability and Environmental Impact of PET Jars

With increasing environmental concerns, PET has gained attention for its recyclability and reduced carbon footprint. Here’s how PET contributes to sustainability:

A. 100% Recyclability:

- PET can be collected, cleaned, and reprocessed into new containers and other products.

- Reduces plastic waste and promotes circular economy practices.

B. Lower Energy Consumption:

- Manufacturing PET requires less energy compared to glass and metal.

- Lower emissions contribute to a more eco-friendly packaging solution.

C. Lightweight Benefits:

- Reduces fuel consumption during transportation.

- Less material waste compared to other packaging options.

7. Customization and Branding of PET Jars

PET jars offer endless customization possibilities for businesses looking to enhance brand recognition. Some popular customization options include:

A. Size & Shape:

- PET jars come in various sizes, from 50g to 1kg or more.

- Different shapes such as round, square, and hexagonal for unique product presentation.

B. Color & Transparency:

- Available in clear, frosted, amber, and colored variations.

- Transparent jars allow customers to see the product inside, increasing purchase appeal.

C. Labeling & Printing:

- Compatible with labels, screen printing, and embossing.

- Helps businesses establish brand identity and communicate product details effectively.

D. Closure Options:

- Various types of caps and lids such as flip-top, screw-on, and tamper-evident.

- Enhances convenience and ensures product safety.

8. Choosing the Right PET Jar for Your Product

Selecting the perfect PET jar depends on the product type and intended usage. Factors to consider include:

- Size & Volume: Ensure the jar size aligns with the product quantity.

- Barrier Properties: If the product is sensitive to moisture or light, opt for PET jars with UV protection.

- Closure Mechanism: Choose appropriate sealing options to prevent leakage and contamination.

- Recyclability: Select recyclable PET jars to support sustainability efforts.

9. Conclusion

PET jars have revolutionized the packaging industry with their lightweight, durable, and eco-friendly properties. They offer cost-effective solutions for businesses while ensuring safety and convenience for consumers. Whether used in food, cosmetics, pharmaceuticals, or household products, PET jars provide superior protection and customization options.

With increasing focus on sustainability, PET continues to evolve as an environmentally responsible choice. By opting for recyclable PET packaging, businesses can contribute to a greener future while maintaining high-quality product standards.

For companies seeking innovative, reliable, and customizable packaging solutions, PET jars remain an excellent choice, balancing functionality, aesthetics, and environmental responsibility.

Reviews

There are no reviews yet.